AMGAS

Alternative Mobility Gas

Goulburn, NSW, Australia

|

|

GOULBURN

ABOUT THE WTE AMGAS GREEN HYDROGEN PROJECTS GOULBURN

Affordable green hydrogen is essential if Australia is to decarbonize its mobility and reduce home electricity. Transport represents 29% of all carbon dioxide emissions and 70% of the electricity supplied to Australian homes and small businesses is still being generated from coal and gas, both of which are reported to impact on climate change.

Green hydrogen needs to be available to the maximum potential number of customers over as wider an area as possible so that refueling FCEVs is not a stumbling block to decarbonizing transport.

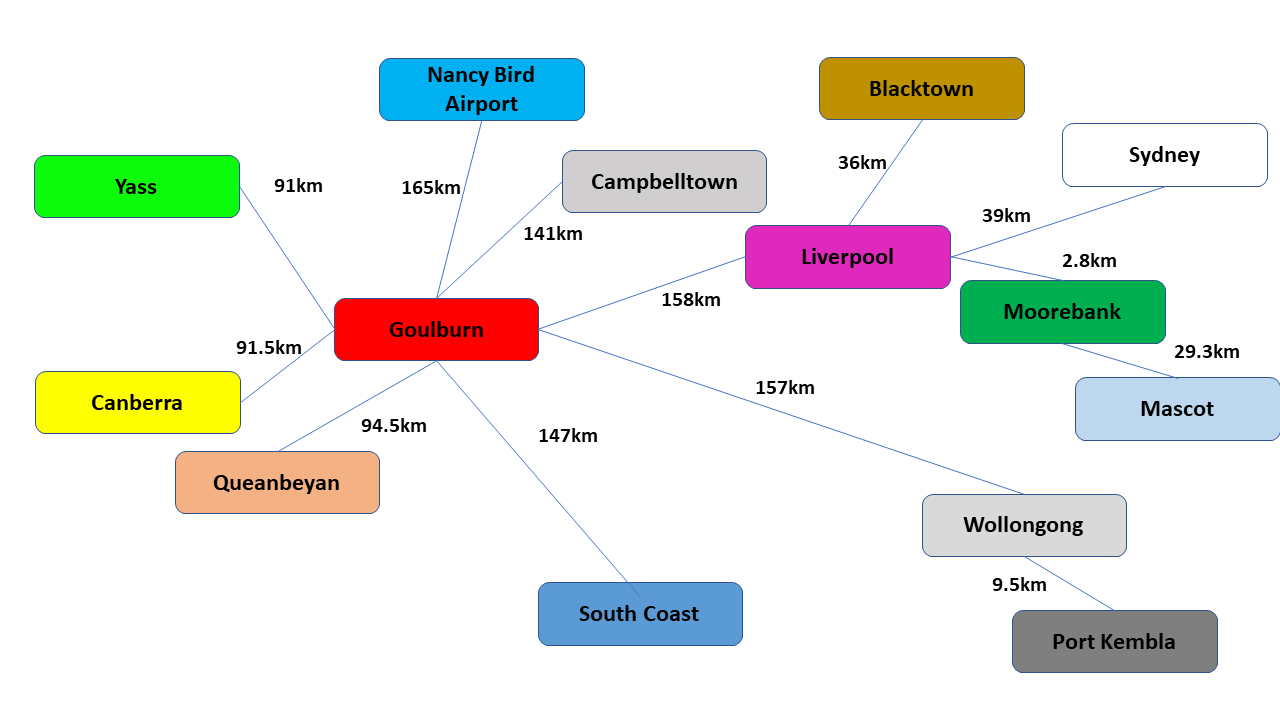

Goulburn, is the first of a matrix of green hydrogen hubs to be developed across Australia, is conveniently located so as to be able to service the major cities of Sydney, Canberra, Queanbeyan, Wollongong, Port Kembla, the new Nancy Bird airport, as well as the central south coast for the producing and distributing green hydrogen. As a hub it provides access for distribution to an area of some 120,000 sq. kms around it as shown below.

|

How the Amgas Plants use wastes to generate renewable energy

The Amgas green hydrogen projects are designed to be vertically integrated WTE (Waste to Energy) plants turning wastes such as wood, food and crop wastes, animal manure, MSW and waste plastic into syngas via Global NRG Ltd.'s patented plasma gasification technology and biogas via anaerobic digesters . Global NRG H2 Ltd is a subsidiary of Global NRG Ltd a WTE, energy storage, and renewable energy group formed in 1976.

The syngas and biogas are then used to generate baseload renewable electricity which is used via electrolysers to produce 99.95% pure green hydrogen from water. Because wastes are constantly re-occurring the generated power is a renewable energy. Unlike solar or wind this energy is not intermittent and can therefore be used where baseload power is necessary such as in the electrolysis of water to make green hydrogen and as backup to wind and solar farms and for peaker power. Biogas can also to be used as a transport fuel in the form of biomethane and as RNG (Renewable Natural Gas). The syngas can be used to produce ammonia and synthetic fuels. Both processes produce by-products. In the case of gasification it's charcoal which is turned into BBQ briquettes and biochar, and from the anaerobic digesters nitrogen-rich organic fertilizers that are sold into the markets generating additional revenue streams that accumulate as a credit in the energy that is then stored in the green hydrogen.

All wastes generate GHG some more than others and this impacts on the environment and is affecring climate change. The Amgas plants will substantially reduce the amounts of waste going to landfill and the GHG they would have generated.

Many wastes bring with them a financial credit. For example, when wastes are sent to landfill they incur gate fees and levies and by diverting these wastes away from landfill into our WTE projects we capture these gate fees and levies meaning that the Amgas plant is already earning an income even before the gases are made and used to generate the electricity, the hydrogen and the by-products. Neither solar nor wind generated electricity are able to earn such credits or produce by-product incomes before or during their generation phases. The result is that the electricity generated and used at an Amgas plant can be up to 70% cheaper than either wind or solar electricity when these credits and income streams are taken into account. The waste credits and by-product income can be viewed as a non-taxpayer funded subsidy. These credits result in Amgas being able to make and sell green hydrogen cheaper than any other method. Global NRG, the parent company has developed a plasma gasification technology for use with organic wastes which will allow up to 40% of waste plastic to be included in the feedstock. As waste plastic normally is destined for landfill, it brings with it the gate fees and levies that would have had to be paid for landfilling it. The waste plastic inoculates the other 60% of the feedstock that may not have attracted landfill fees with the landfill credit while at the same time its helping to reduce the impact of waste plastic now a huge environmental problem, on the environment. Green hydrogen that can sell for as low as $2 per kilo

Making green hydrogen via the electrolysis of water uses a huge amount of electricity and in addition more electricity needs to be used in compressing it so it can be transported. To date the high cost of the electricity used in electrolyzing water has meant that green hydrogen has been too expensive to be able to compete pricewise with fossil fuels, especially in mobility. However in Global NRG H2's case because it is deriving credits from taking the wastes and earning incomes from the by-products the price for the hydrogen sold is relatively insignificant to the overall financial result and hydrogen can be profitably sold as low as $2/kg meaning that FCEVs (Fuel Cell Electric Vehicles) become much cheaper to run on a cost per mile/km basis than fossil fuelled vehicles or even most EVs.

At $2/kg for green hydrogen diesel would need to sell for 44cents/litre to comptete and oil companies can't do that.

Amgas plants are in the unique position in that the more electricity that is needed to be used, the more waste will need to be used and as a consequence the more money it will earn from the wastes and the by-products. Even compressing the gas become profitable as against normally being a cost liability.

Decarbonizing transport using Green hydrogen

Transport represents a major source of GHG emissions due to it mainly being powered by fossil fuels. This is especially true in the case of heavy transport such as diesel trucks and buses.

Green hydrogen at $2/kg is a lower cost fuel than fossil fuels on a mileage basis and emits only a small amount of vapor when used through a fuel cell to power an electric motor as the drive chain, and because the cost per kilometre becomes lower than for the fossil fuelled vehicles presently in use, there becomes a strong incentive from an economic point of view, as well as environmental, to change to FCEVs.

Hyzon Motors Inc.

HYZON Motors is a global supplier of zero-emissions hydrogen fuel

cell powered commercial vehicles, including heavy duty trucks,

buses and coaches.

Headquartered in Rochester, NY and with operations in Europe,

Singapore, Australia and China. Global NRG H2 ltd has

established takeoff agreements with Hyzon covering the green

hydrogen to be produced at its Amgas plants for use in their trucks,

buses and coaches.

With committed orders in Australia for FCEV trucks and buses and access to $2/kg from the

Amgas plants, Hyzon Motors is in a position to offer the heavy

transport industry the opportunity to operate trucks and busses

at a substantially lower cost per km than similarly fossil fueled

heavy transport cutting their emissions to zero.

Global NRG H2 Ltd.'s Amgas plants also have takeoff agreements with Global NRG Storage Ltd for use in its Australian microgrids, and for use in passenger cars assuring it of a solid and viable market for its green hydrogen production.

Cheaper electricity for homes and small business The "subsidized" electricity generated through the Amgas projects is stored in the green hydrogen just like energy is stored in a battery, and is turned back into electricity via a fuel cell. By installing a free microgrid into a home or small business which includes a small green battery pack and a fuel cell that will intermittently keep charging up the battery pack, just like a vehicle charges its battery as it is driven along, the battery pack never runs out of stored energy and the home or small business can leave the electricity grid entirely. Not only will the electricity cost/kWh be lower as there will be no grid cost, no retail margin or daily service charge to pay, the resultant energy bill will be some 50% to 70% lower and as a result there will be less GST to pay. There will be no more outages or blackouts and the home and small business will be powered by 100% renewable energy with no GHG emissions. Back-up for wind and solar farmsBecause the electricity the Amgas plants generate is baseload power and cheap, it can be used on wind and solar farms to backup wind and solar generation when the wind doesn't blow or the sun doesn't shine. It can also be used to provide peaker power and unlike battery storage which lasts for only around 4 hours, renewable gas generation can keep generating for hours and even days or weeks. Environmental benefit

No single renewable energy project being developed in the world can boast the multiple environmental benefits that will accrue from an Amgas WTE green hydrogen project. Which include:

- The opportunity to decarbonize mobility through using affordable green hydrogen that can compete with fossil fuels pricewise without any emissions.

- Reducing the cost of green hydrogen to as low a $2 per kg so that it is more than competitive with fossil fuels in mobility and can be used in homes and small business microgrids to lower the cost of their electricity.

- Removing tens of thousands of tons of wastes and waste plastic per year from landfill and the environment.

- Reducing the landfilling of organic wastes such as MSW, food, wood, sewerage sludge, animal manure as well as waste plastic. Diverting wood and crop wastes away from being burn-off which impacts on the environment.

- Assisting Carbon Capture & Storage (CCS) on a scale equal to millions of tons of carbon equivalent a year by using biochar in soil and concrete.

- Helping to increase crop yields by retaining moisture and nutrients in soils using biochar.

- Turning concrete constructions into carbon sinks via biochar. Creating renewable carbon-neutral energies such as heating fuels, BBQ briquettes, and biomethane.

- Providing standby back-up power to intermittent wind and solar farm generation.

- Taking strain off the electricity grid via decentralized power generation and home microgrids.

- Establishing multiple hydrogen refueling and product outlets within a 190 km radius of the hub, an area that represents some 100,000 km2 which includes 72% of Sydney, all of Canberra and other major regional cities and towns, making it feasible to use low emission FCEV transport.

- Creating hundreds of new direct and indirect jobs in rural zones.

- Increasing the GDP in rural areas.